Sounds good, you can sign me up for both the bigger CPU heatsink, and the bigger PCH heatsink.

However I'd like to know exact prices (for both the ALU versions and the COPPER versions)

+ shipping in total before we conduct business :thumbsup:

I do understand you're not exactly "there" yet with the copper ones, but once you are and can give me a solid quote, shoot me a PM and we'll work out the details

-

I have enough copper for about 5-7 PCH blocks, the copper alone cost me alot of money and copper is harder on tools and takes longer to cut, so expect the copper PCH to be at least £10 more than the aluminium version.

The price of aluminium version will depend mainly on the time it takes to cut it, I'd hope to achieve £25 ish for the aluminium - and that's based on doing 3-4 at once to keep the time efficient.

I recognise this PCH will be the one most people (including myself) are really interested in, so I guarantee I won't delay. I will be measuring the layout in 3D using my machine as a giant 3 axis micrometer to accurately locate x,y,z positions of all the significant parts - so this should reduce the "trial and error" approach of the CPU block I just did and we can almost jump right to the finalising the design stage! -

I would pay you about $50-$80 Australian for the copper PCH cooler (a little extra for your effort). God that aluminium thingy we have is annoying. Maybe up to $150 for the PCH+CPU units.

I am willing to negotiate:thumbsup: -

I want to echo the others that I too am most interested in any improvement of the PCH cooling. Do you have any plans to document the improvement of each material?

-

Keep me on the list for both! I am interested

-

How are my copper kids doing?

-

The Machine is in pieces! I'm finally moving house, so it will be a bit hectic for a few weeks. I'll be back up and designing a PCH cooler as soon as I've found time to setup my new workshop.

=) -

Good to hear! Hope we can get our custom coolers soon!

-

Yes hopefully, its been a long time since I had this crazy dream, I'm not sure how long I thought it would take, but as I generally only have 2 or 3 hours a week spare, it takes a very long time!

-

![[IMG]](images/storyImages/photo25032013220501.th.jpg)

^ posted this photo previously and its still largely the same version (although the holes are now a bit bigger) .. and this is pretty much done certainly in terms of performance it is complete, I will be refining the design (mainly for cosmetic reasons, although being made in my shed, they are probably never going to compare to the mass produced, sand blasted/polished electroplated off the shelf items) changes are as follows:

- the 2, 7mm holes towards the end of the heat pipe will become 6.5mm "squares" being milled with a non-centering 5mm endmill leaving a 5mm radius in the corners - as the round 7mm drilled holes are messy and ugly, and leave a bad finish!

- the 7mm holes nearest the GPU will be made in to 6.5mm slots - as the holes are close to edge so leave messy thin bits that don't offer any real cooling benefit.

- the remaining very small bit of cooling fin (where the heatpipe cutout re-joins the main profile) will be removed as it is sharp and won't offer any beneficial cooling.

- the latch/catch cut outs will be cut using a 5mm cutter to give cut at 90deg rather that the curved cuts that you see in the edges now.

- The profile will be cut out leaving 2 tabs per block for final release, this should give a better surface finish and speed up the deburring & finishing process

- facing will be done with a 12mm endmill

- I may invest in a polishing mop/wheel to gently polish the base to give a more attractive look if requested?? although it wont be a mirror type finish and offers no real benefit over the 1000grit flat diamond file finish - this will be an option at extra cost as polishing is time consuming - I'd have to give it a go and see how long it might take me, I could always stick the thermal tape to a piece of backing paper and you can polish it yourself - to a mirror finish if you can! before applying and trimming the thermal tape - I think I'd prefer this if I where a buyer - keeps the price down??. -

Meaker@Sager Company Representative

You really do remind me of the guy who created custom blocks over at futuremark and then went on to start his own small business, would be great having 3rd party cooling options for the most popular notebooks, even if they were not hugely cheap.

-

Well that would be nice, but my priority is work and university, so my amateur CNC skills are progressing slowly lol =)

- It's good fun though, one of the frustrating things being a design engineer is not getting to make the parts you design, often I don't even see them they're at the other side of the world lol ! -

I did model a nice tungsten carbide coated liquid cooled ball valve that will be hitting over 600deg C 24 hours a day, 7 days a week! - and thats getting installed locally to me which is nice, just the ball out of the valve weighs as much as a small car, and thats WITHOUT any water in it!

-

Cheaper the better.

I have already invested too much money on this little thing....

I don't think the cosmetics really matter, as long as it keeps our laptops nice and cool after a little OC. I would be happy

-

Meaker@Sager Company Representative

I'd worry more about function too since these are internal components.

-

I've made all the above changes, and I'm hoping to get the machine unboxed, rebuilt and ready tonight (or at least nearly ready) to cut some coolers tomorrow. I redesigned the cut process to include 4 coolers, so hopefully in under 48 hours, I'll have 4 or 8 of them ready for posting, I'll post them in the marketplace (if they get removed due to my low post count you'll have to wait lol)

The design should look very different - the profile has changed, I've tightened the bends, tidied up the edges etc. I'm think they will look much better.

Friday or Saturday design will start on getting a CNC'd PCH cooler

Stay tuned, thanks for sticking with me

:hi2: -

Meaker@Sager Company Representative

Good luck with that

Yeah the market rules are what they are, you can maybe talk to a moderator and see. -

![[IMG]](images/storyImages/photo25042013220730.th.jpg)

^ I'm not getting any faster at this lol, still taking over an hour so I've been at this nearly 7 hours......... and we have just 4 blocks, almost available...... just a little tidying up to do. The are a much nicer neater looking block.

I'm unable to offer any "thermal tape" (the stuff I have is awful, its probably making things worse), the better way would be with thermal epoxy if you have any. I do want to design a "bolt through" type so thermal paste can be used, but this requires the purchase of replacement extended bolts

I have a fairly major issues with my machine, I'll have to investigate further, its basically losing count just on the Y axis, eventually it works itself nearly a whole millimeter out of position. my only thoughts (after checking all cables and connections and allowing the machine to cool down and trying again) are......... since I lowered the torque (by fitting the 3k3 fixed resistors) its missing steps as the bed is still tight because I've not done the brass gib strip upgrade yet, due to "techincal" issues when manufacturing the replacement gibs...

just on the Y axis, eventually it works itself nearly a whole millimeter out of position. my only thoughts (after checking all cables and connections and allowing the machine to cool down and trying again) are......... since I lowered the torque (by fitting the 3k3 fixed resistors) its missing steps as the bed is still tight because I've not done the brass gib strip upgrade yet, due to "techincal" issues when manufacturing the replacement gibs...

anyway, here's the chaos if any of you ever wondered where these are being produced, still not unpacked everything after the move, so the garage is packed I've been working around it all today

![[IMG]](images/storyImages/photo25042013142558.th.jpg)

-

Meaker@Sager Company Representative

Mmmm garage electronics and machinery, it's where all the fun stuff gets to happen

-

I'm in the process of ordering some Sekisui #5760 direct from Japan - I'll be fitting the blocks with this as soon as it arrives, it is the branded stuff, not the white paper stuff of "questionable origin"

I'll re-spool some in to 50mm by 500mm rolls - keep an eye on the market place in a few weeks - handy stuff to have in a draw for those odd jobs/modifications -

I'll be purchasing one of these when more become available. Great work Calibre41!

-

No trouble at all thanks for tuning in!

Work began last night (rather slowly...) on the chipset block..... I'll get the design knocked out tonight with a bit of luck, given that the prototype I made works and fits, that's a large amount of the work done.

My P150EM with 7970m will be arriving at the end of the week - so I'l have peek in to this =) -

Meaker@Sager Company Representative

If working on that remember that the P170EM and 370EM all share the primary GPU heatsinks so designs for that are pretty universal.

-

Yes I was discussing these possibilities with Prema not long ago, its possible that these share the cpu & gpu cooler maybe?

P150HM, P151HM, P170HM, P170HM#, P150EM, P151EM, P170EM.

plus the P370EM shares the GPU heatsink... ?

Its all good news to me =) -

Meaker@Sager Company Representative

Yes that's true and it looks to carry over to the new models too.

-

Sounds good, I was hoping to have a P150EM by the end of the week but I'm getting delayed making the order and now have a £540 utilities bill to settle ( halve of this is the heating bill for the workshop lol, no more heating in the workshop, I'll put a f*&^ing jumper on

)

)

-

Meaker@Sager Company Representative

That's the same heating bill as our flat, try closing the roof lol.

-

keep us tuned!!

-

I see copper is back to sensible ish prices, I've request some quotes from local companies, hopefully they'll be happy to deal with private individuals and hobbyists etc. I've requested a fair amount of flat copper bar, so hopefully it will be worth there while but I want a specific C145 "Tellurium Copper" so it could be £200 to £250......... This P150EM purchase might have to wait a month while I save up..........

EDIT....

Yes, prices are reasonable, I'm getting some bar stock, and a very small amount of 100mm wide plate for personal use =) -

yes, yes, yes !!!! :thumbsup:

I'm getting excited now, precious copper is on its way to me

I'm hoping to get the design for the PCH done by the end of the week, and then I'll have to design a jig to make it in, and we're set to go!!!!!!!!!!!!!!

(I also have to fix my machine - this makes me less excited..... it is losing steps..... essentially its taking 200,000 forwards, and 199,900 back....... so eventually, it creeps off in one direction - this is obviously a very, very serious issue........ I have no idea what has caused it, I've not had this problem before that I have noticed, I'll swap to my 4th spare channel and see if its a controller issue........)

- this is obviously a very, very serious issue........ I have no idea what has caused it, I've not had this problem before that I have noticed, I'll swap to my 4th spare channel and see if its a controller issue........)

-

If you wait a month for the P150 EM purchase, well then make it a P150 SM purchase (Haswell)!

-

yeah I know, but I'm on a budget - especialy with my recent heating bill

!!!

!!!

Haswell processors will not be cheap second hand for 6 months at least, and I don't have any I can swap from any other machine obviously as they aren't compatible, in addition to this, I don't think the architecture offers any benefits to folk with dedicated graphics solutions,

I'm working on the understanding that the 8-series Lynx Point PCH won't be compatible with Sandy/Ivy Bridge CPUs'

my plan with the P150EM was to use the 3360m from my W110ER and find a cheap quad core once the prices drop.....

I would like to be at the cutting edge...... maybe we'll see about selling the W110 in a month to fully fund a big Haswell 150SM - but I do love this W110 its so portable and powerful - I had it hook up to my 1920x1080 monitor for the first time last night, expecting to have to reduce a bit of detail, but nope, its powered through, so i pushed the detail up a notch, just to see what might happen, and it fluctuated between 45 and the 59limit i have, so I left it at that !! - really pleased with it, its been so great, best laptop I've ever had, I sold my 460m i7-620m Alienware M15X for this little W110, and I've never looked back! -

Whats the news on the W110ER ones? I'm ready to send you some money for one when you are. I'm gonna get some new TIM while im at it or do I need thermal tape? The temps on my new lappy are a little high but the 3720 overclocks nicely.

-

I'll be getting the Sekisui #5760 direct from Japan, so once it arrives, I'll apply it and I'll have 4 blocks ready to go out

I think I might already have sold them all with pre-orders I will go through my private messages and build a list, and contact people on the list, giving them 48hours to respond and 7 days to pay before moving to the next name.

I will be unable to make or send any blocks between the 12th and 21st of May due to other commitments so hopefully this Sekisui tape arrives, with time to apply it and contact people so I can post some out on the 11th.

The PCH blocks are still not made or finsihed design, they are very tricky to make. I'm looking at a 2.1mm air gap, with a 0.4mm fin (in copper) and maybe 0.8mm in aluminium. getting this tiny 2.1mm slot cut to a depth of 4 or 5mm is the most challenging part and requires a very delicate approach. -

I'll be doing a quick write up on the heatink using Seksui tape, should be another week or so before i get to it though.

-

Cool, cheers mate, fingers crossed

- does it get extra points for "unique style" !!

:thumbsup: -

This seems like a very beneficial upgrade to my w110er! Sign me up (if there are any left T_T)

-

Absolutely unique style. Very professionally done.

-

Bargain incoming from the states,

picked up a R216.42-01030-AI10G

^ I get excited about these things, to me this is like the machining equivalent of getting an 3940xm......... lol

I will be able to make some very fine coolers with that baby.... hopefully it should last long enough to do at least 5 or 10 PCH blocks

^ the design potential just improved................ -

Very exciting indeed !

-

Meaker@Sager Company Representative

Lol, every field has its own toys

Have fun with it, looking forward to seeing the designs.

Have fun with it, looking forward to seeing the designs.

-

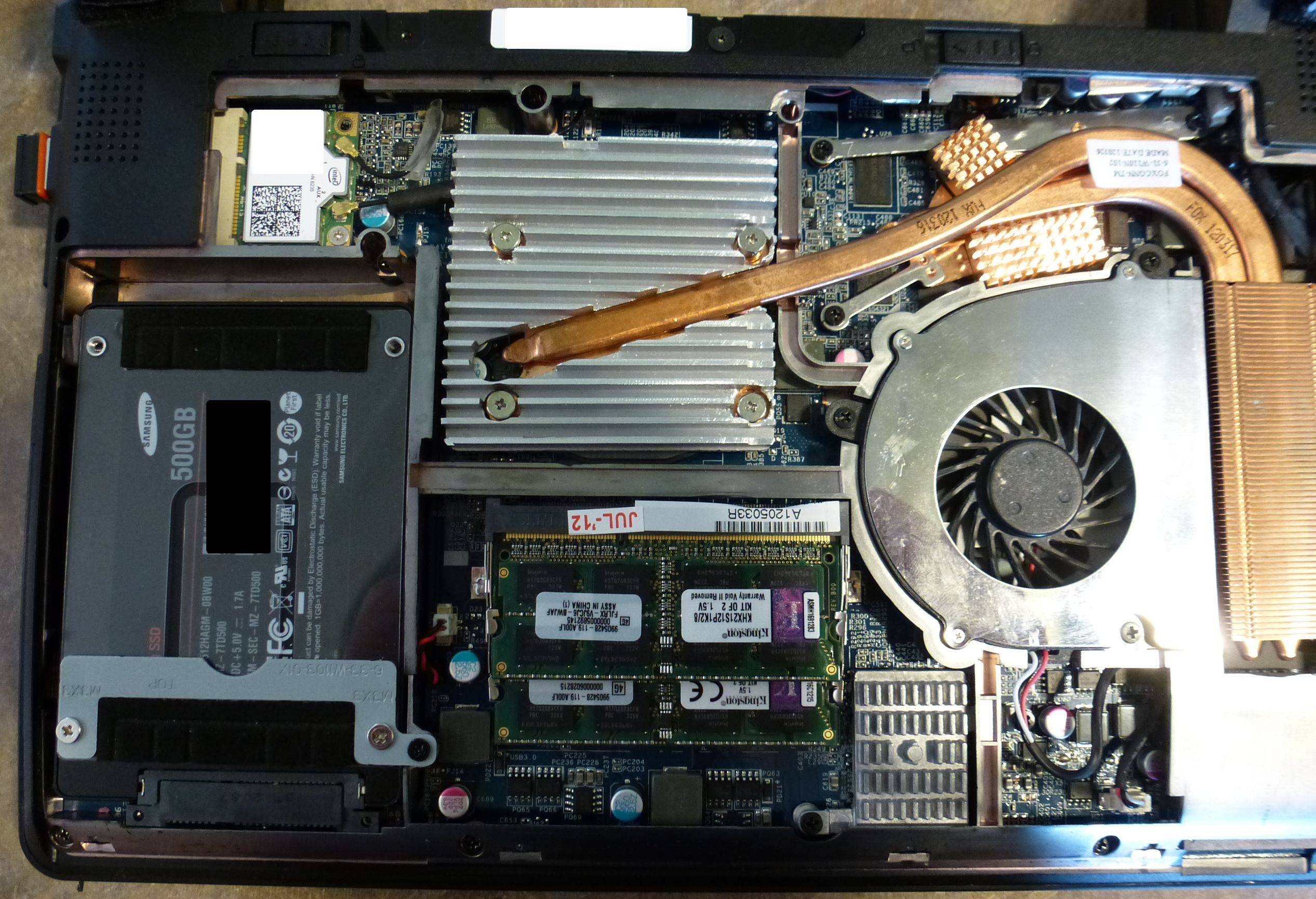

Here is Calibre41's CPU block installed on my W110ER:

![[IMG]](images/storyImages/cjWr37n.jpg)

Installation was as simple as peel and stick, holes lined up with the screws as did the slot with the heatpipe. The inboard holes are a bit off center from the screws but it still fits, and could probably add a little more aluminum where it ends at the heatpipe since there seems to be ample clearance. I guess these are kind of notes to Calibre41. In any case very well done and a nice addition.

I did a few basic temperature tests and found that it was as effective as the stick-on copper RAM heatsinks I had on there (6 total), although this looks more professional than a bunch of loosey goosey RAM heatsinks applied. I had a clearance slot open on my bottom cover from my previous addition of a fan mod, but since I removed the fan I had just the opening with a grille over it. I also had the original bottom panel which I put on there and temperatures are the same with or without a vented bottom panel. You can see how mine was set up previously by visiting my post here: http://forum.notebookreview.com/sag...om-copper-machined-coolers-2.html#post8901792

I'm still considering the mod where I use an mSATA to SATA adapter to free up room behind the SSD to place a blower fan and knock out the wall between SSD compartment and the CPU to blow directly on this heatsink (see link to my previous post). It may offer even more effective cooling. Although with propping up the back, latest EC, BIOS mods, etc it's surprisingly cool with anything I do. -

Meaker@Sager Company Representative

Heatpipe lengths can vary a little so it may be a case of being safe.

-

Yes, 2 advances on this front, I've adjusted the holes, and made some in to slots etc. as per the previous change log, I also made the slot a bit narrower near the screw head. I also actually have some totally new hole positions to try which I measured with my machine while I was getting a rough layout for the PCH, so they're likely to be alot more accurate, It will be interesting to see how they compare.

![[IMG]](images/storyImages/photo3xjz.jpg)

NO CLEVO'S WERE HARMED IN THE MAKING OF THIS PRODUCT..........

^ Yes I noticed about 4mm difference between mine and my mates, so I took the distance, and doubled it plus my existing margin.... I'll shave it down, and see if I can also taper it off to an even more narrow slot (taper it a couple of mill maybe) to fit better, it is a bit of an eye sore and I have noticed, I just didn't want any not to fit

Here is pic of the slightly modified type... ( I thought I'd uploaded this already....)

![[IMG]](images/storyImages/photo4owb.jpg)

-

Awesome! So looks like that mobo is being put to good use! Glad I didn't pitch it!

-

Some very nice stuff in this thread. Looking forward to something similar for the P170EM.

-

Me to

- I have vowed to finish this W110 before moving on......

- I have vowed to finish this W110 before moving on......

-

oooh let us know when you are ready for orders

-

Meaker@Sager Company Representative

You have people excited now lol. Im not sure how much the em series has to give for an extra plate but worth a look.

-

Yeah, I'm sure what ever space there is in there, I will PLASTER it with custom heatsinks............... =)

I received my copper stock today.... a few bars for the PCH coolers, and a 100mm wide plate..... for "other" Clevo related projects....most of my time right now is spent thinking about work holding and designing and making some sort of jig to aid manufacture.

and while I'm here, let me stir your brain juices with a "did you know" relating to some of things going through my brain when trying to perfect upgrades and replacements for my "Clevo" cooling.....

DID YOU KNOW...... that the molecules of gas inside a vapour chamber (if perfectly purged of any other molecule) travel at 1225 km/h and this is the speed (of sound yes) in which a "perfect" heat pipe would transmit heat from one end, to the other.... just in case you ever wondered "how good" a heat pipe is. it will also transfer heat a very long distance with hardly any effect on efficiency.

What if I told you, I want to REMOVE the traditional heat-pipe altogether.......and replace it with a more exotic version of the same science......

exotic means expensive, but I'm throwing price out of the window given that I'm the designer and manufacturer, and this is my own hobby

I'm in need of some data..... lots of data..... specifically the chemical composition and properties of the working gas, and its vacuum pressure..... I think I'm going to end up just doing my own research here and gathering figures. I know my design is superior but the chemical composition, negative pressure and volume/ratio of the working fluid will make or break the design....

Clevo W110ER Custom copper machined coolers

Discussion in 'Sager and Clevo' started by Calibre41, Oct 15, 2012.